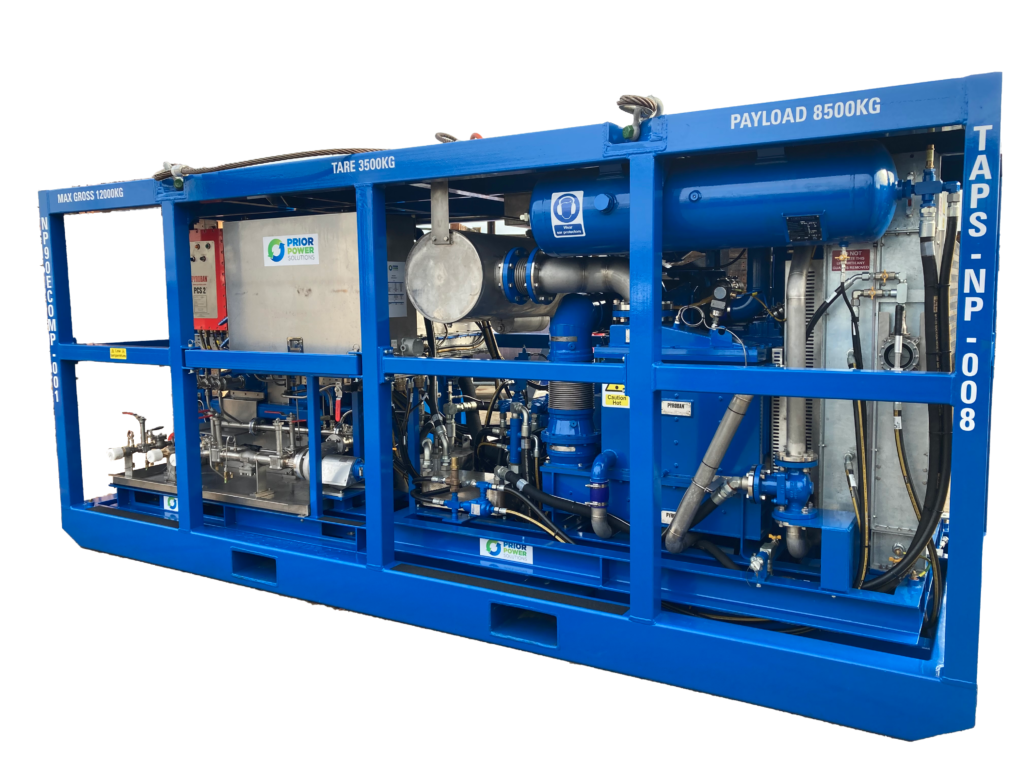

NITROGEN PUMP MANUFACTURE

High quality 90k nitrogen pumps

Our 90k nitrogen pumps are not only manufactured to a very high standard using top quality components and materials, but they are designed with ease of future maintenance and straightforward operation at the fore. Additionally, our modular build process allows for future-proofed equipment available in faster lead times.

As a world-leading manufacturer, we’ve always prided ourselves in the design of our 90k nitrogen pumps, continually evolving to meet changing customer needs. Our latest design ensures our units are ready for future advancements in technology such as more energy efficient engines, or changing operating needs.

Constructed as self-contained units, our 90k nitrogen pumps are capable of pumping and vaporising 90,000 SCFH at 21°C and pressures up to 10,000 psi when supplied with liquid nitrogen from a suitable tank.

Available as standard, CE-marked, ATEX or bespoke, the primary components of our units are a diesel engine which drives the hydraulic pumps via a gearbox, a hydraulic driven triplex pump, liquid nitrogen engine coolant vaporiser/heat exchanger and a certified steel lifting frame/skid which houses these components.

The unit is also equipped with a hydraulic tank, fuel tank, oil coolant heat exchangers, high quality hydraulic hoses, low and high temperature liquid nitrogen and GN2 stainless steel pipework and a single control panel for operating both the engine and pumping system.

The frame is a single open skid frame with protective crash beams, fork lift pockets and a four-point lift system and equipped with ISO corner castings to suit 10′ ISO twist lock locations.

For details of our wider range of nitrogen pumps click here.